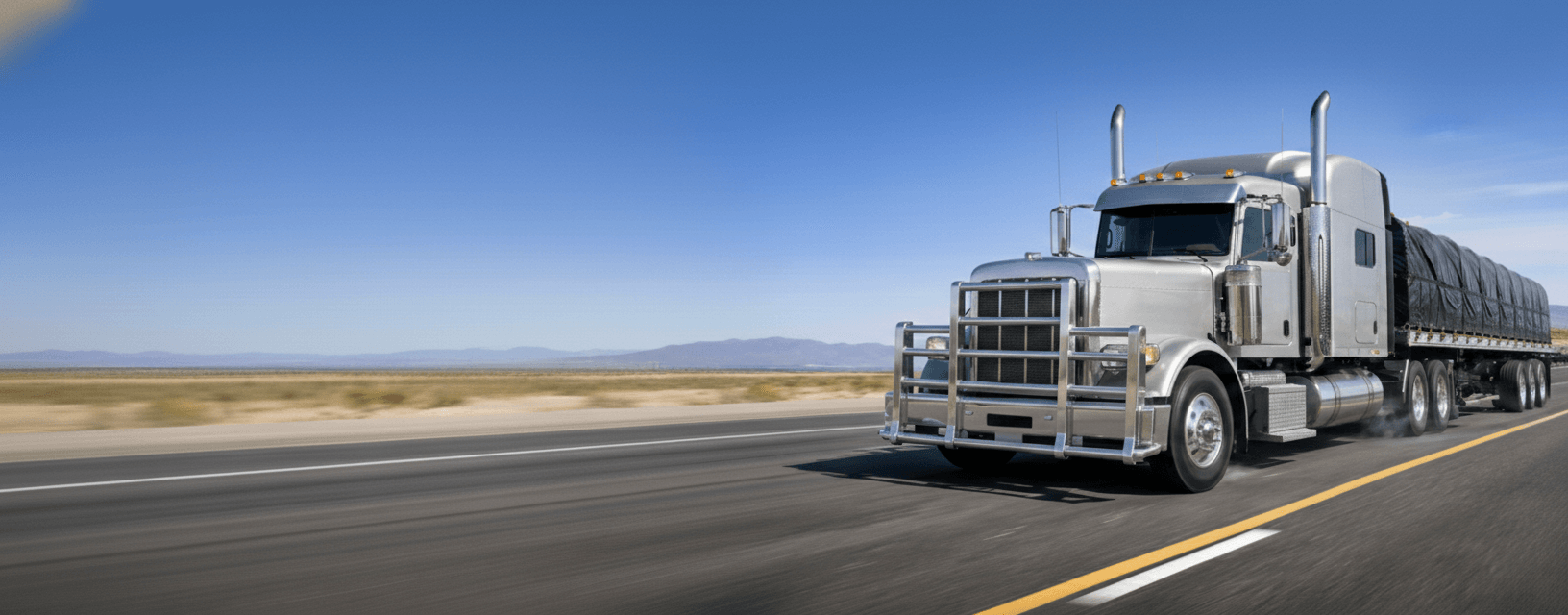

Heavy-Duty Truck

Protection

Manufacturer

Moose Bumpers, Grille Guards & Truck Protection — engineered for extreme conditions, built for lasting performance.

OEM/ODM Truck Protection Products

Heavy-duty truck bumpers, guards, and accessories manufactured for North American applications — with full OEM/ODM customization support.

Moose Bumpers

Heavy-duty front protection for long-haul trucks. Engineered to deflect wildlife impacts and protect drivers in extreme conditions.

View Product DetailsGrille Guards

Stylish front-end protection that enhances vehicle presence. Multiple finish options available to match your brand aesthetic.

View Product DetailsPickup Bumper

Rugged protection designed for the pickup truck market. Built tough for off-road adventures and demanding work site conditions.

View Product DetailsTool Boxes

Secure, weather-resistant storage solutions for trucks. Heavy-gauge aluminum construction with corrosion-resistant finishes.

View Product DetailsTruck Bodies

Custom aluminum truck bodies built to spec. Lightweight yet durable construction for maximum payload capacity.

View Product DetailsAccessories

Fenders, chain hangers, mounting hardware and more. Complete your truck setup with our range of quality accessories.

View Product DetailsNeed help finding the right product for your application?

View All ProductsWhy Partner With Brontec

We combine advanced manufacturing capabilities with deep market expertise to deliver truck protection products that exceed North American standards.

Quality Assurance

Multi-stage inspection and testing ensures every product meets or exceeds industry standards.

100% Fitment Guarantee

Precision jigs and CMM verification ensure every hole aligns perfectly with vehicle specs.

20-30% Faster Lead Times

Streamlined production and dedicated capacity get orders to you ahead of schedule.

Dedicated Support

Your dedicated account manager ensures clear communication and responsive service.

We eliminate the common headaches of overseas manufacturing that cost you time and money.

Your Trusted Partner for Heavy-Duty Truck Protection

Founded with a mission to provide North American fleets with superior truck protection, Brontec has grown into a leading OEM/ODM manufacturer of moose bumpers, grille guards, and pickup bumpers. Our state-of-the-art facility combines advanced manufacturing technology with skilled craftsmanship to deliver products that exceed industry standards.

From Concept to Container: Our OEM Process

A streamlined manufacturing process designed for efficiency and quality. Partner with us for reliable OEM/ODM support from start to finish.

Inquiry

Share your requirements

Design

Engineering review

Sample

Prototype approval

Production

Mass manufacturing

QC

Quality inspection

Delivery

Global shipping

Ready to start your OEM project with us?

Engineering Excellence

Every product is built with precision engineering and premium materials. Discover what sets our truck protection apart from the competition.

Premium Series

Premium Series

Material Thickness

Heavy-gauge steel and aluminum alloy construction for maximum durability and impact resistance

Weld Quality

AWS-certified welders ensure every joint meets strict structural integrity standards

Hole Position Accuracy

CNC precision machining guarantees perfect vehicle fitment every time

Impact Testing

Every design undergoes rigorous impact testing to simulate real-world collision scenarios

Interested in learning more about our engineering standards?

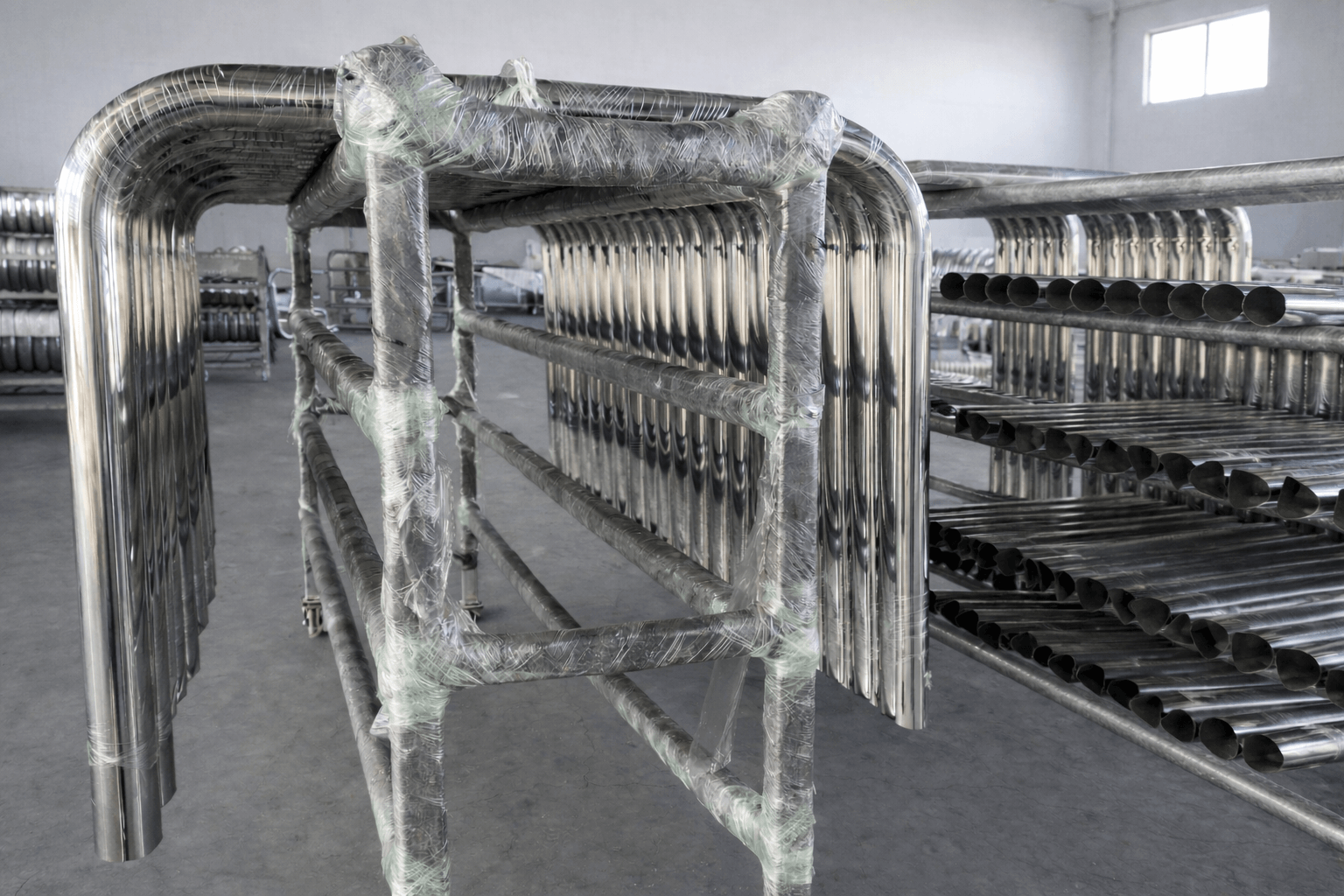

Explore Our Engineering CapabilitiesManufacturing Excellence

Take a visual journey through our production facility where precision engineering meets hands-on craftsmanship.

Welding Station

Certified welders working with MIG/TIG equipment under strict quality protocols.

CNC Bending

Precision press brakes achieving ±0.5mm tolerance on every bend.

Laser Cutting

Fiber laser systems cutting complex profiles with clean edges.

Surface Treatment

Powder coating, galvanizing, and chrome plating capabilities.

Assembly Area

Final assembly and hardware installation with torque verification.

Quality Inspection

Dimensional verification and visual inspection before packing.

See our manufacturing process in action with a live virtual tour.

Quality Assurance

Every product undergoes rigorous quality control at each stage of production, ensuring consistent excellence from raw material to final shipment.

Material Certification

All incoming steel and aluminum verified against mill certificates. Material thickness, grade, and composition confirmed.

In-Process QC (IPQC)

Critical dimensions checked at each production stage. Weld penetration, bend angles, and hole positions verified.

Weld Inspection & NDT

Visual and non-destructive testing on all structural welds. Full penetration and absence of porosity verified.

Dimensional Accuracy

Final products measured against CAD specs using precision instruments. Mounting points verified to ±0.5mm tolerance.

Packaging Verification

Export packaging tested to withstand ocean freight. Crush tests and drop tests ensure damage-free delivery.

Final QC (FQC)

Complete inspection checklist before shipment. Quality reports and certificates prepared for each batch.

Need detailed quality documentation for your procurement team?

Where Our Products Are Deployed

Heavy-duty applications with defined load, vibration, and service risks.

Oil & Gas Remote Operations

Off-road access · Corrosive environments · Heavy accessories

View ApplicationOEM & Fleet Standardization Programs

Platform consistency · Repeatability · Supply continuity

View ApplicationOff-Road Pickup Applications

Frame-mounted loads · Winch forces · Trail vibration

View ApplicationExplore all deployment environments and application guides.

View All ApplicationsEngineered for Major North American Truck Platforms

Our truck protection and accessory products are designed for compatibility with widely used Class 8 and pickup truck models across North America.

Vehicle platforms our products are engineered to fit. All trademarks are the property of their respective owners and are used for reference only.

Need a fitment solution for your specific vehicle model?

Industry Insights

Stay informed with the latest trends, technical guides, and industry knowledge about truck protection products.

Loading latest articles...

Want more industry insights and technical guides?

Visit Our BlogFrequently Asked Questions

Find answers to common questions about our products, processes, and services.

What is the minimum order quantity (MOQ)?

Our standard MOQ varies by product type: Moose Bumpers start at 50 units, Grille Guards at 100 units, and Tool Boxes at 200 units per order. For new OEM partnerships or custom designs, we can discuss flexible arrangements during initial consultations. Volume discounts are available for larger orders.

Can I order below the MOQ for trial purposes?

Yes, we offer sample orders for quality evaluation before committing to full MOQ. Sample quantities typically range from 1-5 units depending on product complexity. Sample costs may be higher per unit but are often credited back on subsequent bulk orders that meet our standard MOQ requirements.

How do you ensure sample-to-production consistency?

We use precision jigs and fixtures created during the sample phase for all production runs. CMM verification ensures hole positions match approved samples. Our quality team conducts first-article inspections and maintains detailed production control documents throughout the manufacturing process.

What is the sample development cost?

Sample costs vary based on complexity and materials. Simple modifications to existing designs may have minimal costs, while completely new designs require tooling investment. We provide detailed cost breakdowns upfront, and sample costs are often credited back on production orders above certain quantities.

What is the standard production lead time?

Standard production lead time is 25-35 days from order confirmation, depending on order quantity and product complexity. Rush production (15-20 days) is available at additional cost when capacity allows. We provide real-time production updates throughout the manufacturing process.

How long does shipping take to North America?

Sea freight to West Coast ports typically takes 15-20 days, and to East Coast ports 25-30 days. We work with reliable freight forwarders and can arrange door-to-door delivery. Air freight options are available for urgent shipments at additional cost.

What packaging options do you offer?

We offer multiple packaging options: standard export packaging with wooden crates, retail-ready packaging with your branding, and custom packaging solutions. All packaging is tested to withstand ocean freight conditions and includes protective padding to prevent damage during transit.

Can you add our logo and branding to packaging?

Yes, we provide full private labeling services including custom packaging with your logo, branded instruction manuals, and product labels. We can match your existing brand guidelines or help develop packaging designs for new product lines.

Which truck models do you support?

We manufacture products for most major North American truck brands including Freightliner, Peterbilt, Kenworth, Volvo, Mack, International, and Western Star. For pickup guards, we cover Ford, Chevrolet, GMC, RAM, and Toyota. Custom fitments for other makes and models can be developed upon request.

How do you ensure proper vehicle fitment?

We maintain an extensive database of vehicle specifications and mounting points. For new applications, we request detailed measurements or reference parts. All new designs undergo physical test-fitting on actual vehicles before production approval to ensure bolt-on installation.

Still have questions? Our team is ready to help.

Contact UsGet In Touch

Start Your Project Today

Whether you need a quick quote, technical consultation, or want to discuss a long-term OEM partnership, our team is ready to assist. Send us your requirements and we'll respond within 24 hours.

Email Us

Call Us

+86 185 6186 5879

+86 137 0896 2673

+86 133 7133 5587

Response Time

Within 24 Hours

Location

Sancheng Road and Guoren Road Intersection, Pingdu, Qingdao, China

Request a Quote

Your information is secure. We never share your data with third parties.